4 Telltale signs it's time to replace your existing Fan

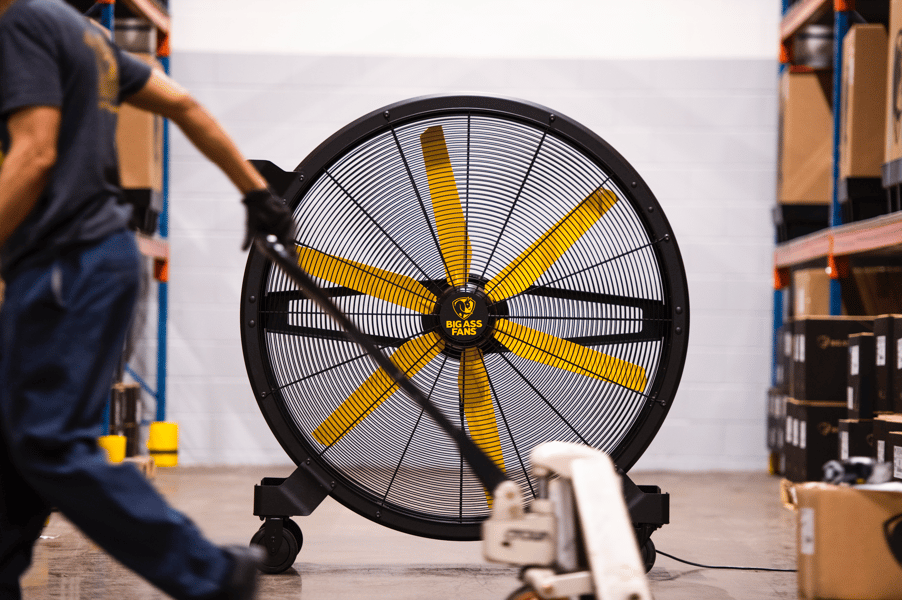

Some might say we’ve become quite good at our jobs - experts in the fan industry. Over the last 14 years, we’ve seen it all when it comes to fans. This has opened our eyes to new and innovative ways to ensure that our fans are built to last and give you the best return. We’ve outlined 4 telltale signs it’s time to replace your existing fans.

Weak Airflow

We have seen many cases where large warehouses are not utlising fans effectively, to get sufficient airflow. Often the fans are not big enough to circulate air through a large building and if it is, it's being blocked by racking or other obstructions. It can be difficult knowing where optimal positioning is, so before replacing your existing fans, we recommend using a 3D modelling software that can map the airflow output of a fan in your space. This will help you visualise where the best place is to install your fan, to effectively circulate air, with no stagnant zones.

Ticking, wobbling, rattling

Many industrial fans are not built for the harsh environment that is a warehouse. In a short amount of time, these fans become less durable and perform inefficiently, either at a slower speed or with annoying ticks and wobbles. When looking to replace your fan, look for fans with motors of a high IP rating. Fans IP65 and IP66 rated typically mean the enclosed fan motor is protected from harsh environments. We also believe these maintenance-free claims also need to be backed up with warranties to support (somewhere between 10 - 15 years).

Lack of Comfort

In many cases, we’ve seen warehouse employees working with only a few stand-alone fans. This is a huge concern for employee safety and efficiency. Heat can create fatigue, effecting worker productivity and creating a higher risk for accidents around the warehouse. By having the correct type and number of fans in your space, the people working underneath the fans can feel cooler by up to 6 degrees, significantly reducing the risk of heat stress and heat-related injuries.

Material Durability

We see many cases where smaller items (in contrast to other warehouse materials) are often pushed aside and resolved with cheap and quick-fix products. This is obviously not an economically sustainable move, with these products often being of low quality and inevitably needing replacement. By investing in a product that is durably engineered with premium materials ensures its longevity. Again, look at products that are backed up with a 10 to 15 year warranty to gauge the quality.

Over many years in the industry, we have clobbered, dropped and thrown our fans to ensure you are getting a product that will work when you need it most. We have built our fans to withstand almost anything and in the process discovered some of the common issues found in other industrial fans.

Need an assessment on your current cooling solution? We’ve got you covered! Sign up below for a complimentary site visit. One of our Airflow Experts will come out to your facility and give you a customised recommendation to replace your existing fans, focusing on your areas of concern.

Sign up for a FREE Site Visit

Article Credit: Smart Daily